The goal was to design a throttle pedal that would be used in our 2024 FSAE car, and to improve the weak areas from the previous year’s design. Some of the design considerations that were explored included overall pedal geometry and materials, while ensuring that the design would seamlessly integrate into the pedal box’s mechanical linkage system. The main differences in the designs generated for the new throttle pedal stemmed from geometry variations. I explored many different designs such as curved vs flat faces and tapered vs straight angle attachments between the pedal face and arm. I was also able to vary the layers of carbon fiber and the type for the layup schedule.

Last Year’s Pedal

Areas to improve:

The previous composite throttle pedal had been made of two sperate pieces for the arm and the face which were epoxied together after curing. This design was unstable under off-centered loads, and one of the areas that experienced critical failure was the pedal arm which delaminated from the core and face. While it was able to be repaired with a wet layup, this is not a good solution. Accordingly, it was one of the main areas I wanted to focus on improving with the new pedal design.

The First Iteration

Coming up with designs:

I knew that I wanted to improve the stability of the connection between the pedal arm and face. Last year’s pedal was made with a separate carbon fiber arm and face that were epoxied together. There was a failure where the face and arm separated and had to be put back together with a wet layup. To minimize the chance of that failure recurring, I explored designs that had the pedal arm and face in the layup together. I also looked at tapered arm geometries to help reduce stress concentrations in the carbon fiber.

Manufacturing:

A prototype composite throttle pedal was designed in CAD based on the concepts I explored. The core was a CNC cut rohacell foam arm piece, pedal face, and flag for a total of three pieces. 3 layers of twill weave carbon fiber were done in a 0/90-degree layup schedule around the foam core, and it was oven cured with vacuum bagging for debulking. Beam bending calculations were done in Excel to come up with a starting point of three layers of carbon on all faces and the fiber orientation was aligned with the peak stresses to give the most mechanical benefits. An aluminum bracket was made by bending sheet metal and belt sanding one end to round the edges and was epoxied onto the pedal arm after curing for the prototype.

Testing:

I designed a testing jig to load the prototype throttle pedal until failure. Holes were drilled in the aluminum bracket for mock attachment pieces to mimic the force loading effects of the pivot point and throttle stop mechanisms. Hanging masses were used to simulate the loads of the driver’s foot pressing on the pedal.

Billet was added in increments to the testing jig up until failure occurred at 40 lbs (~178N). The pedal arm failed at the interface between the pedal face and the arm. This was expected as there would be force concentrations at the 90-degree bend in the carbon fiber layers at the face. However, this was not where the highest bending moment stresses in the arm would occur, which means the stress concentrations at the interface exceeded the peak bending moment at the base. I was not satisfied with the result of the test loading so I decided to add additional layers of carbon fiber to the next iteration to increase the strength of the face that failed.

The Second Iteration

Updated Composite Pedal:

Based on the failure mode during the test loading of the prototype, I decided to adjust the design to make the arm and face out of one piece of foam instead of two. This made the face flush with the pedal arm and completely removed the 90-degree angle responsible for the stress concentration in the carbon layers. As a result, the overall pedal face is approximately 1/3 inch thinner for the same thickness of pedal arm. I also added another taper between the face and arm to further reduce the force concentrations where it broke during proof loading and added additional fillets around the arm and rear face connection. The flag size was kept the same as this was determined by driver feedback from last year and further supported by driver satisfaction with pushing on the prototype. Instead of making the aluminum bracket out of bent sheet metal I used a CNC machined aluminum bracket that I created a toolpath for and ran the machining job myself on a 3-axis mill in the student maker space. This allowed for higher precision and tighter manufacturing tolerances to be achieved. It was then co-cured with 2 layers of film adhesive between the carbon pedal arm and the bracket. I also sandblasted and Aluma-prepped the inner surfaces of the bracket for better adhesion of the two faces. The same cure cycle was used as the prototype, along with vacuum bagging to increase the consistency of manufacturing.

The Back-up Aluminum Pedal

For risk management reasons we decided to make a backup pedal with an aluminum arm in case the composite one ended up breaking at a test day or during the competition. The face of the prototype was in good condition, so a slot was cut into it to epoxy in the aluminum arm. This was done to save time and materials instead of making an entirely new face. This pedal was not intended to ever be used, but due to an unfortunate failure of the composite pedal during pedal box re-assembly, it was used for one of our test days.

We were unsure of the exact reason for the composite pedal failure as it was not being loaded as expected when it broke. The pedal base was being wrench tightened and a team member was using the pedal arm to brace the wrench when tightening. We suspected that the pedal either failed in fatigue because it broke on the rear side (compression face when under loading conditions) or from the local compression applied unexpectedly by the wrench.

To prevent further failures due to our uncertainty around the composite pedal breaking, we decided to change the design to an aluminum arm and composite face. While this means that we did not end up using a fully composite pedal at the competition, we felt that it would be the safest option in the amount of time remaining before we had to leave for the competition.

The Final Pedal Iteration

Final Design Adjustments:

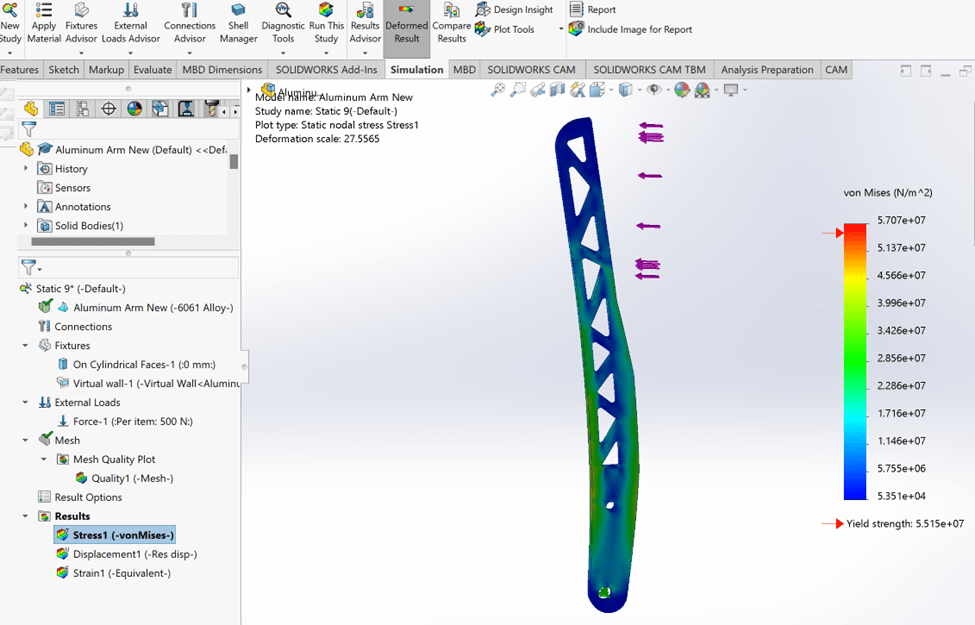

I designed and created a CAD model of the selected aluminum throttle pedal arm design in SolidWorks. I figured out the required thickness of the arm by completing simple beam bending hand calculations, as the maximum width was constrained by the throttle stop dimensions. I then verified this by applying iterative loading simulations using the FEA functionality in SolidWorks and using topology optimization to get an idea of how I could weight optimize this part. Finally, I added triangle cut outs which reduced the overall part weight by over 20% and added fillets and chamfers at the force concentrations to complete the design.

Manufacturing:

The pedal arm was water jet cut out of 6061 aluminum billet. I used my SolidWorks model to create a DXF outline of the cut, which I used to created the tool path in the water jet’s operational software and then ran the cut myself in the machine shop.

The composite pedal face was a rohacell (structural foam) core with 3 layers of 0/90-degree layup schedule twill weave carbon fiber. I added tapered slots on the back face to constrain the pedal arm and ensure that it was aligned correctly during the co-cure. The arm and face were co-cured with 2 layers film adhesive between them, and the arm was Aluma-prepped to improve the adhesion between the arm and the face. I chose to add film adhesive because The pedal was vacuum bagged, and oven cured. I was also able to apply this pedal face design to the brake pedal, which interfaced with the master cylinders and the brake pedal arm.

The final pedal interfaced successfully with pedal box and ran at test days and competition without any issues. Currently we are keeping the other aluminum pedal as a backup as it also ran successfully during a test day. While we were not able to run a fully composite throttle pedal this year, we are confident in our decision to return to an aluminum arm. There was not enough time to appropriately test and determine the exact causes of the failure of the composite pedal intended to run this year, but this is something that would be explore further after competition.