This project involved designing a carbon fiber FSAE steering wheel for Formula UBC’s 2025 vehicle with an integrated dashboard and paddle shifter mechanisms.

Current Steering Wheel Issues:

The current handle geometry and surface texture does not provide adequate grip, requiring significant grip strength and leading to unnecessary fatigue. They are also too thick for small hands and don’t effectively constrain the driver’s hands during cornering.

Ergonomic Factors:

Extensive driver feedback was gathered throughout this project to influence the design process. Drivers of various sizes and preferences were consulted to ensure the steering wheel design was both functional and comfortable for everyone. One of the most significant challenges was accommodating different driver sizes and preferences within a single design. The wheel had to provide adequate space for larger drivers while maintaining comfort and ease of use for smaller drivers.

To help address this, anthropometric data was incorporated into the design process. For example, measurements such as hand breadth, grip span, and thumb length were considered to optimize the handle dimensions and positioning. These adjustments ensured the wheel could comfortably accommodate a wide range of hand sizes, enhancing control and reducing driver fatigue.

I was also actively involved in the design process for both the chassis team and the driver controls team. This collaboration was essential to ensure that the steering wheel design harmonized seamlessly with the rest of the car’s setup. By working closely with these teams, I coordinated the steering wheel’s ergonomics with the overall driver positioning, ensuring that the seating, pedal arrangement, and control interfaces worked together cohesively. This approach minimized ergonomic compromises and enhanced driver comfort and performance during operation.

Design Process:

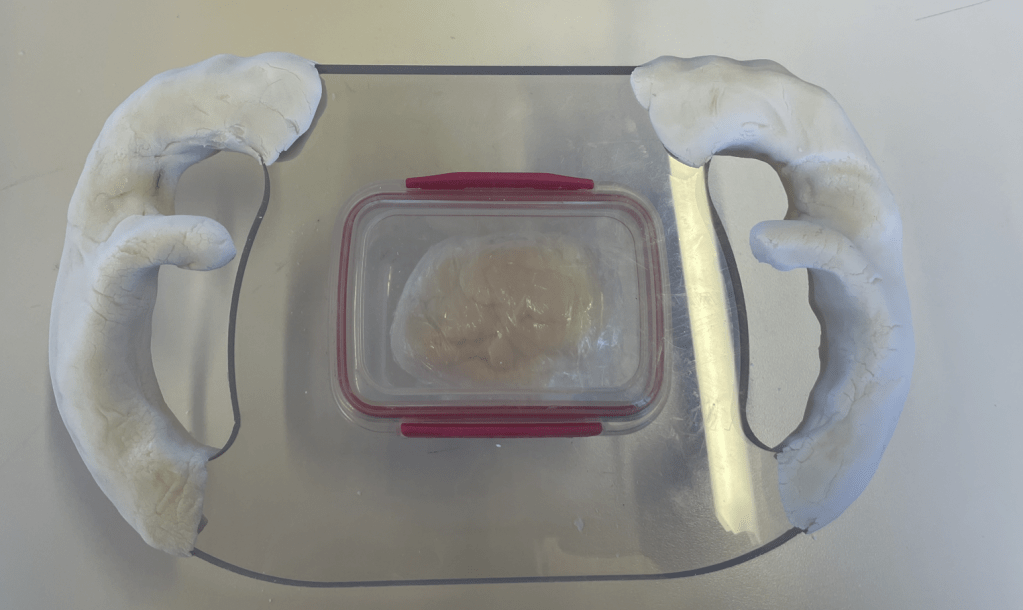

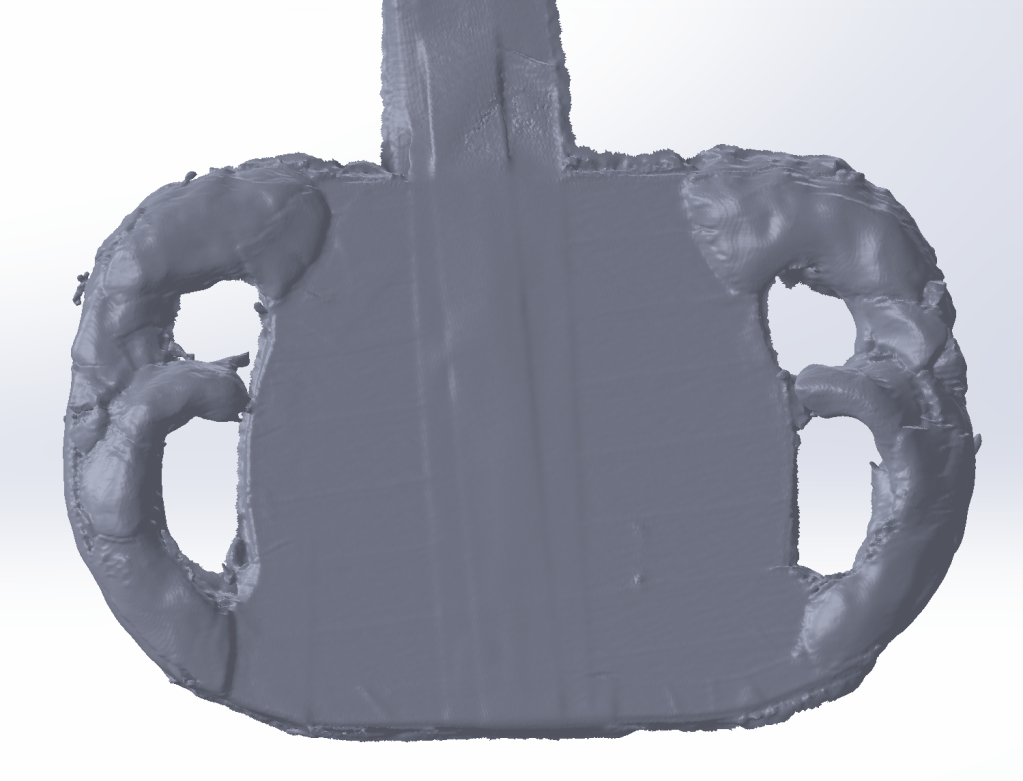

I created a template steering wheel with hand-molded grips, which was used for low-cost, rapid prototyping and allowed me to gather extensive driver feedback on various design iterations. This process was critical in finding the optimal grip configuration for drivers of all sizes and quickly validating the design with the drivers in real life. Once the ideal grip design was finalized, I 3D scanned the the prototype to generate a digital model that I used to generate comprehensive models for the thumb supports.

Using this model, I developed the thumb supports which enhanced the overall grip of the handles. These supports, were 3D printed and have been integrated on top of the structural handles of the wheel. It is beneficial to keep the thumb supports separate from the structural shell of the wheel, because it

These supports were manufactured using 3D printing, which allowed for further rapid prototyping and easy adjustments based on additional driver feedback once run at test days and local AutoX events. The finalized thumb supports are epoxied to the wheel, ensuring durability while maintaining the ability to refine or replace them if needed. This simple modification offered a low-risk solution that delivered substantial benefits for driver comfort and performance. It combines thoughtful design with adaptable manufacturing, providing an effective improvement to the steering system.

The thumb supports provide additional leverage points and improve landmarking, helping drivers consistently locate their hands on the wheel. This ensures a precise and repeatable grip, which is especially important for the technical driving needed in FSAE events. Driver feedback strongly supports the addition of the thumb supports as drivers felt that they provided a substantial reduction in perceived steering effort, reduced fatigue during endurance events and improved driver comfort and ergonomics.

To address the issue of insufficient grip on the handles, stick tape was applied to improve grip. This solution proved to be both cost-effective, adding under $1 in material costs, and highly practical. The tape is durable, does not damage driver gear, and can be easily applied post-manufacturing. Additionally, it can be removed and replaced without impacting the underlying structure of the handles. During test days, including in wet conditions, the stick tape performed exceptionally well and received positive feedback from drivers. This reinforced its effectiveness as a simple yet reliable solution to enhance grip and overall driver confidence with the steering wheel.

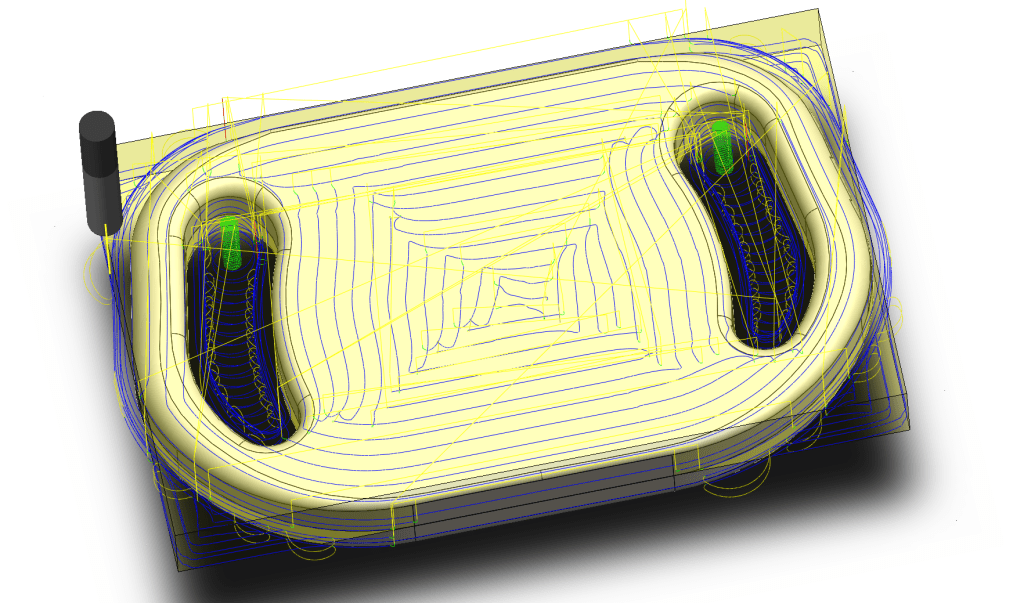

Shell Manufacturing:

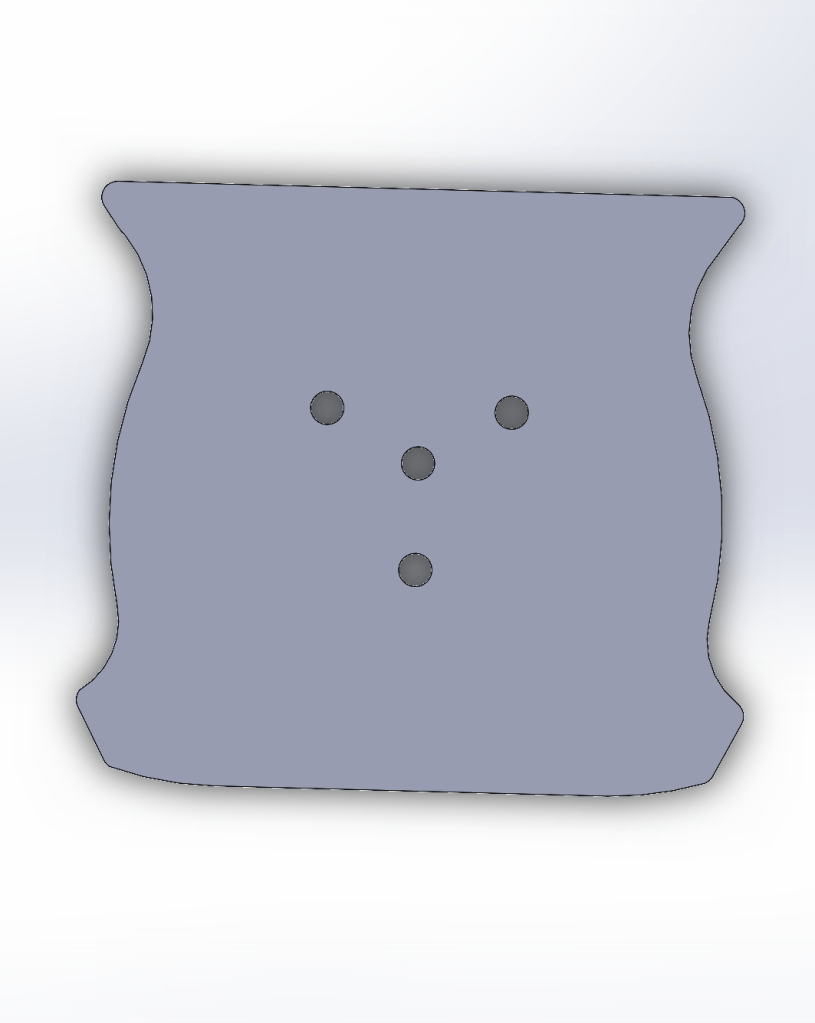

Locating holes for the quick-connect mount were incorporated into the rear face of the steering wheel to enhance the alignment between the backplate and the core during the layup process. These features streamlined assembly by ensuring precise alignment without adding significant time to the core manufacturing process. This adjustment greatly improved the accuracy of the backplate placement and simplified assembly during later manufacturing stages, contributing to a more efficient and reliable manufacturing workflow.

Waterproofing the Electrical Enclosure:

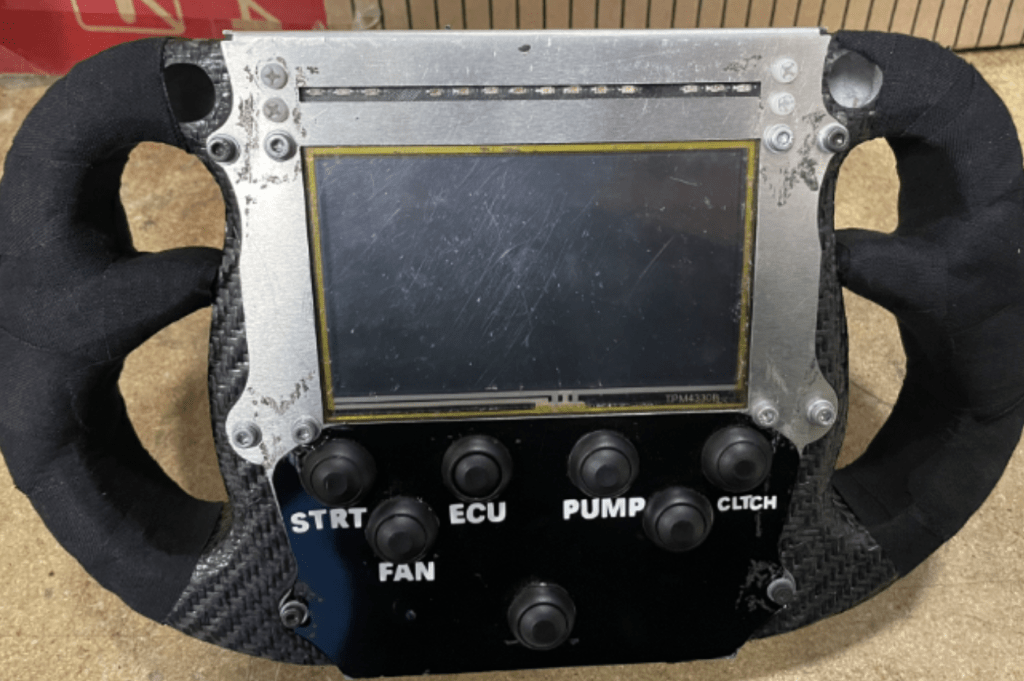

The integrated dashboard is one of the highlights of this steering wheel design. By housing the integrated LCD display screen, RPM shift LEDs, and dashboard buttons within the hollowed-out center of the wheel, the design optimizes cockpit space and reduces overall weight.

To ensure the electrical enclosure is well-protected, a custom 3D profile gasket, resembling a rounded half O-ring, is used to improve the seal between the carbon faceplate and the wheel shell. The rounded gasket enhances the clamping pressure and waterproofing ability of the faceplate, while being permanently adhered to the shell side to minimize leakage. The carbon surface’s finish will also be refined using a partial flat plate mold during layup and post processing, further enhancing the gasket’s performance.

The wheel is designed to allow for quick and easy access by the electrical team while maintaining reliable waterproofing. To achieve this, the gasket system has been optimized for reusability and ease of assembly. The flexible 3D-printed gasket provides a robust seal while enabling the enclosure to be opened and resealed without compromising the waterproofing integrity. The fasteners have also been strategically placed and increased in number to ensure uniform clamping pressure. Since the gasket is permanently adhered to the shell, it remains in place, and eliminates the need to realign the gasket during reassembly.

The design aims to achieve an equivalent waterproofing standard of IP66, capable of withstanding powerful water jets, even though IP65 would suffice for most wet conditions. This reflects a conservative design approach, offering a safety margin for mock tests since we do not have access to a formal certification. While it is very unlikely under the expected loads, if gasket creep relaxation occurs, replacements can be easily manufactured due to the simplicity and affordability of the 3D printing process.

Paddle Shifter Mechanisms:

The paddle shifter mechanisms were seamlessly integrated into the steering wheel assembly to ensure comfortable and confident shifting. The paddles were aligned horizontally with the center of the thumb supports and positioned within easy reach of the driver’s fingers. This allows for quick and precise actuation without compromising grip or control of the wheel. This integration not only enhances the ergonomics of the steering system but also contributes to a smoother and more responsive driving experience.

The 2025 Formula UBC Racing Steering Wheel: